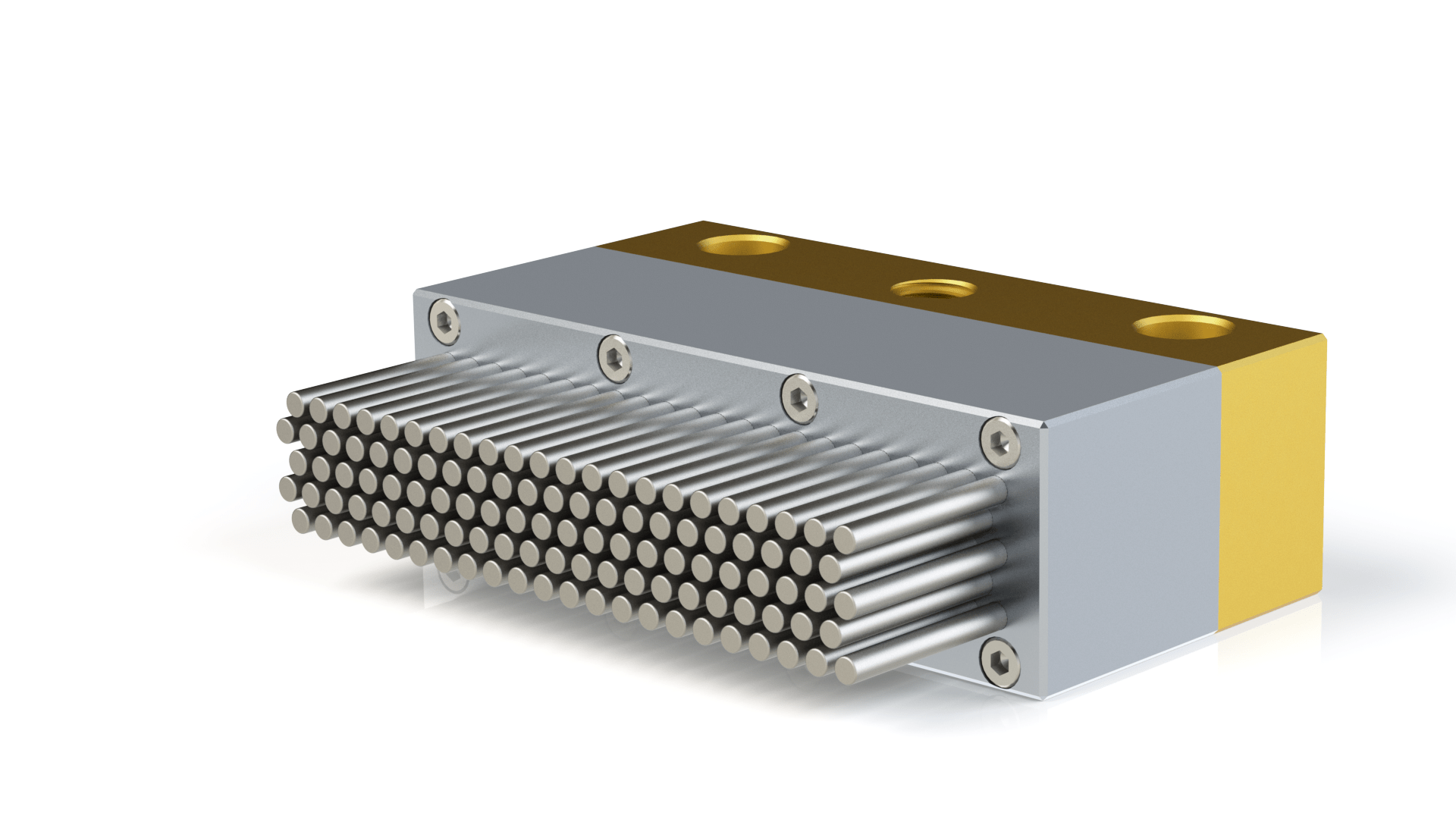

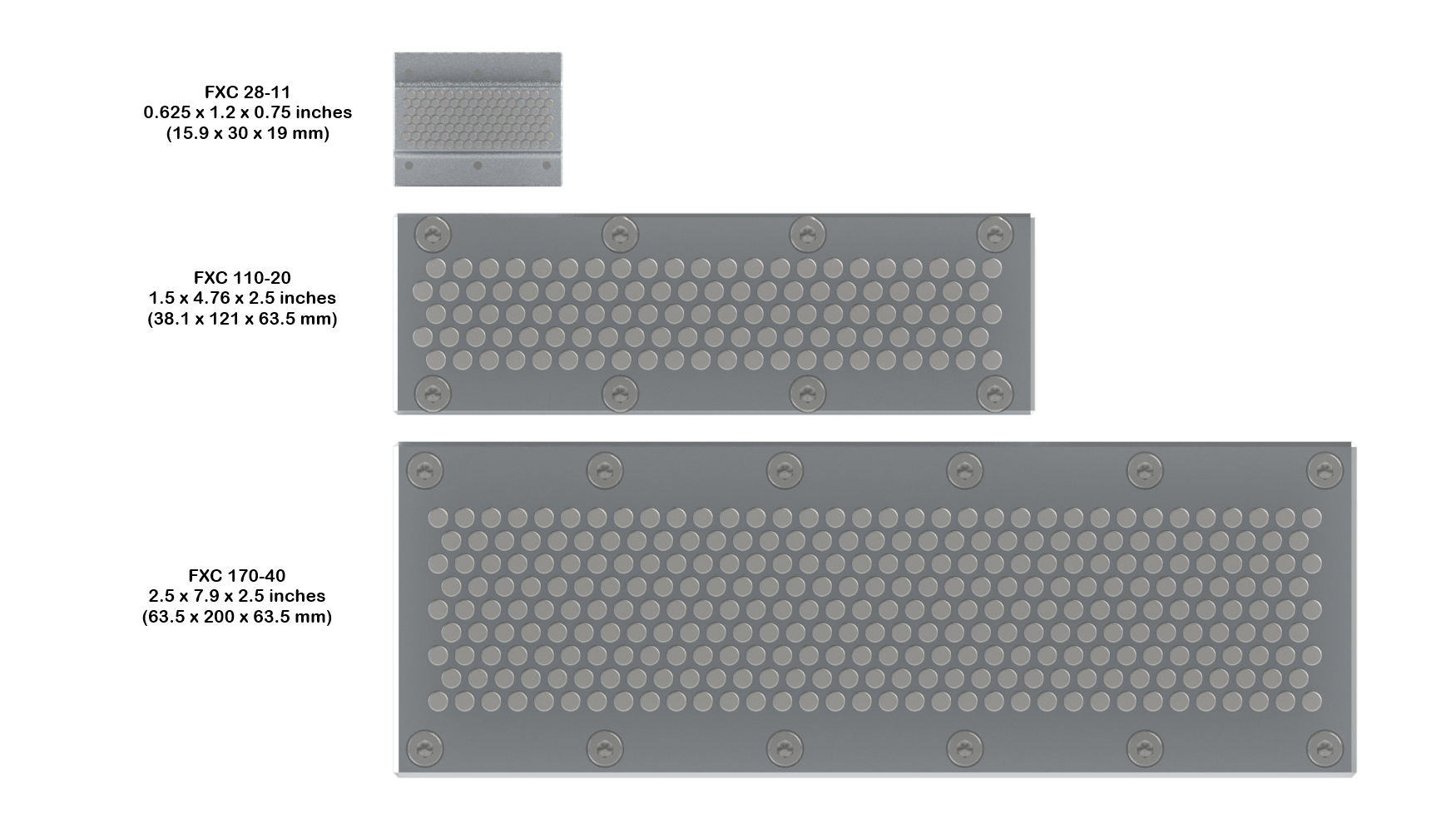

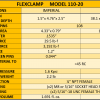

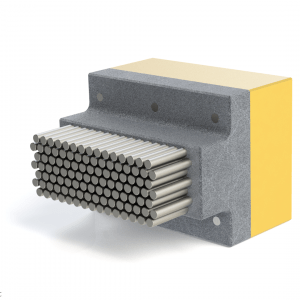

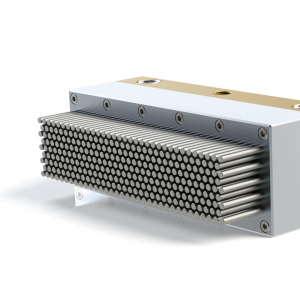

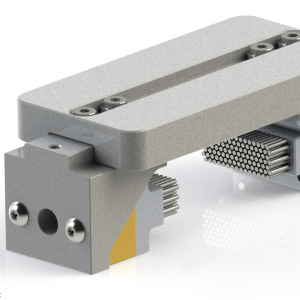

FlexClamp™ is a revolutionary engineering design introduced into the market aiming to solve one of the greatest problems industry wide, particularly for the machining sector, quality inspection, assembly, and automation. FlexClamp™ is a Patent Pending design made of multiple pins that adjust virtually to any object and format. The pins adapt to the shape of the contour of objects to be fixed, obtaining a precise, rapid, and free of distortion clamping with a perfect fit each time. The system is powered by hydraulic pump or pneumatic line, allowing to obtain an elevated clamping force, or smooth and delicate in case of use on fragile objects, alike. By utilizing a pressure regulator, it is possible to obtain a fine adjustment applicable to all sorts of materials and shapes.

If you need to customize the FlexClamp™ for your particular application go to: FlexClamp Customized Models

Our clamping device has a unique design that confers flexibility, robustness and precision. Thanks to FlexClamp™ you will be able to reduce the massive amounts of accessories, such us: clamps, fixtures, jigs, jaws, etc. that need to be selected and/or designed and manufactured for each particular project or application.

FlexClamp is an extremely versatile device, you and your team will be the most adequate to select and visualize the best ways to apply it to your application; but here are some examples to give you a head start for your imagination. Remember FlexClamp can be mounted in all directions around. Some examples where FlexClamp can be mounted are: T-slot machine table, grid plates, subplates, tombstone, on vise, custom made structures and accessories, robot arms or gripper and in combination with locating pins, guide pins or dowel pins and other accessories. You can even make simultaneous clamping with multiple FlexClamp™ by arranging a centralized actuating system, feeding a series of FlexClamp devices, where these could be clamping many parts or multiple orientations and surfaces of one bigger component.

FlexClamp is constructed of heavy duty materials to give efficient operation in systems using petroleum base fluid in hydraulic systems or lubricated and filtered compressed air. Optional seal materials are available for operation with other fluids and/or environments.

The FlexClamp with “Standard” feature option has a temperature working range of -30° to +120°C (-22°F to 248°F). In case your application is subject to temperatures out of this range or you selected other FlexClamp feature option contact our engineers to sales@flexclamp.us. Temperatures closer to the limit of the range will affect the working life. Low temperatures could increase leaks, while higher temperatures could increase material fatigue and seals friction. Other environmental conditions could also affect the device. Please contact us.

IMPORTANT: note that the aforementioned temperature range is only indicated for the FlexClamp not considering the effect of the temperature to other components or power fluid used.

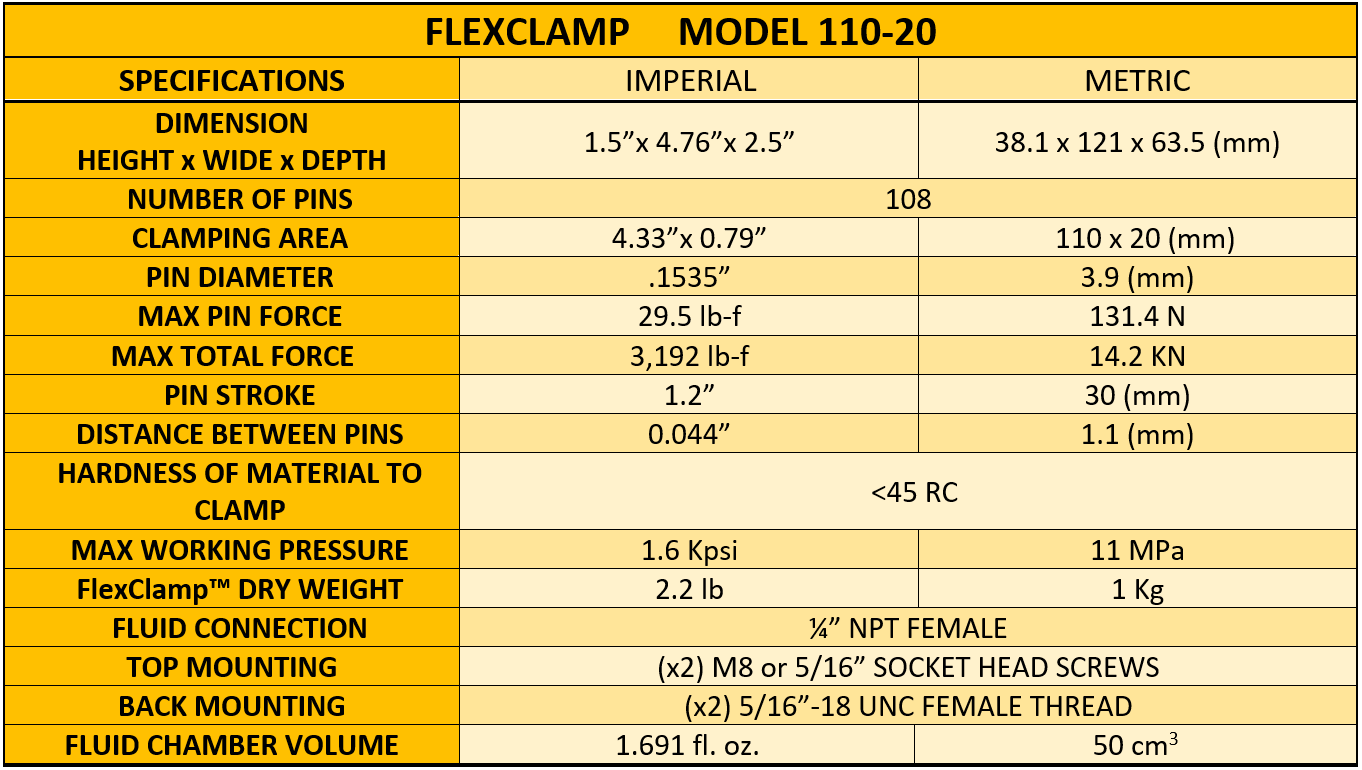

IMPORTANT NOTE: All specs, dimensions and colors are subject to change without notice or may differ depending upon export destinations and manufactured year. MAZONTECH LLC is not responsible for any inaccuracies contained herein. Please consult our sales representative or MAZONTECH LLC regional offices before designing or purchasing any product.

Customization

Many of our products and accessories can be customized to fulfill your application requirements.

Go to: FlexClamp Customized Models

Some examples of customizations could involve: material selection, coatings, sealing material, dimensions and shapes, mounting accessories, etc.

Please send as many specifications and detailed description as possible, including sketches, working conditions, environmental conditions, material compatibility, dimensional limitations and any other constrain.

Send an email to sales@flexclamp.us or with the button MAKE AN ENQUIRY describing your application case. Our engineers will shortly answer and start working together with you towards finding the best solution.

Backorders

Backorder is available for products that are in production or are planned to be produced in the coming month. Please make an enquiry and we will answer with an estimate delivery date. Only for reference, backorders are usually ready during the term of 15 to 30 business days.

Free Shipping Conditions

MAZONTECH LLC offers free standard shipping to customers within the US territories. Orders qualifying for free standard shipping will be shipped using USPS.

In stock orders are shipped from California within one business day and depending on your location, the order may take 3-6 business days.

If you prefer other courier, please contact us by making an enquiry (button above) or send an email to sales@flexclamp.us. Shipping charges will apply.

For international shipping, please contact us by making an enquiry (button above) or send an email to sales@flexclamp.us. Shipping charges will apply

All delivery dates are approximate and Seller shall not be responsible for any damages resulting from any delay. Regardless of the manner of shipment, title to any products and risk of loss or damage shall pass to Buyer upon tender to the carrier at Seller’s facility (i.e., when it’s on the truck, it’s yours).

Unless otherwise stated, Seller may exercise its judgment in choosing the carrier and means of delivery. No deferment of shipment at Buyers’ request beyond the respective dates indicated will be made except on terms that will indemnify, defend and hold Seller harmless against all loss and additional expense. Buyer shall be responsible for any additional shipping charges incurred by Seller due to Buyer’s changes in shipping.

See all our Offer of Sale and Warranty in the following link: Offer of Sale and Warranty

Offer of Sale & Warranty

Follow the link by clicking on: Offer of Sale and Warranty

Cancellation & Refund

Read our cancellation, refund, return (non-return) and exchange policy by clicking here: Cancellation and Refund Policy

Sales/Use Tax Exempt

If you require to make a purchase exempt of sales/use tax, you will need to send an email to Sales@FlexClamp.us with a copy of your sales/use tax exemption certificate, making sure the following mismatches are not present in the document:

- Incorrect claim type/certificate not accepted

- All fields have been filled

- It is signed (signature of accepted signer) and dated.

- Missing issue date

- Document (letter, email) not recognized by state taxing authorities

- Includes name or address other than direct buyer and seller

- Wrong state ID

Also include a Purchase order for the products you wish to include in your order, and upon reception we are going to verify your exemption certificate and reply to your email with an attached invoice for the product you ordered excluding the sales tax.

In case there is a mistake or your exemption certificate is not valid we will inform you, and you can make your on-line order as usual.

IMPORTANT NOTE: Document must be sent and verified before we can exempt sales tax to your transaction.